Working principle of cold water tank of laser marking machine

Working principle of cold water tank of laser marking machine

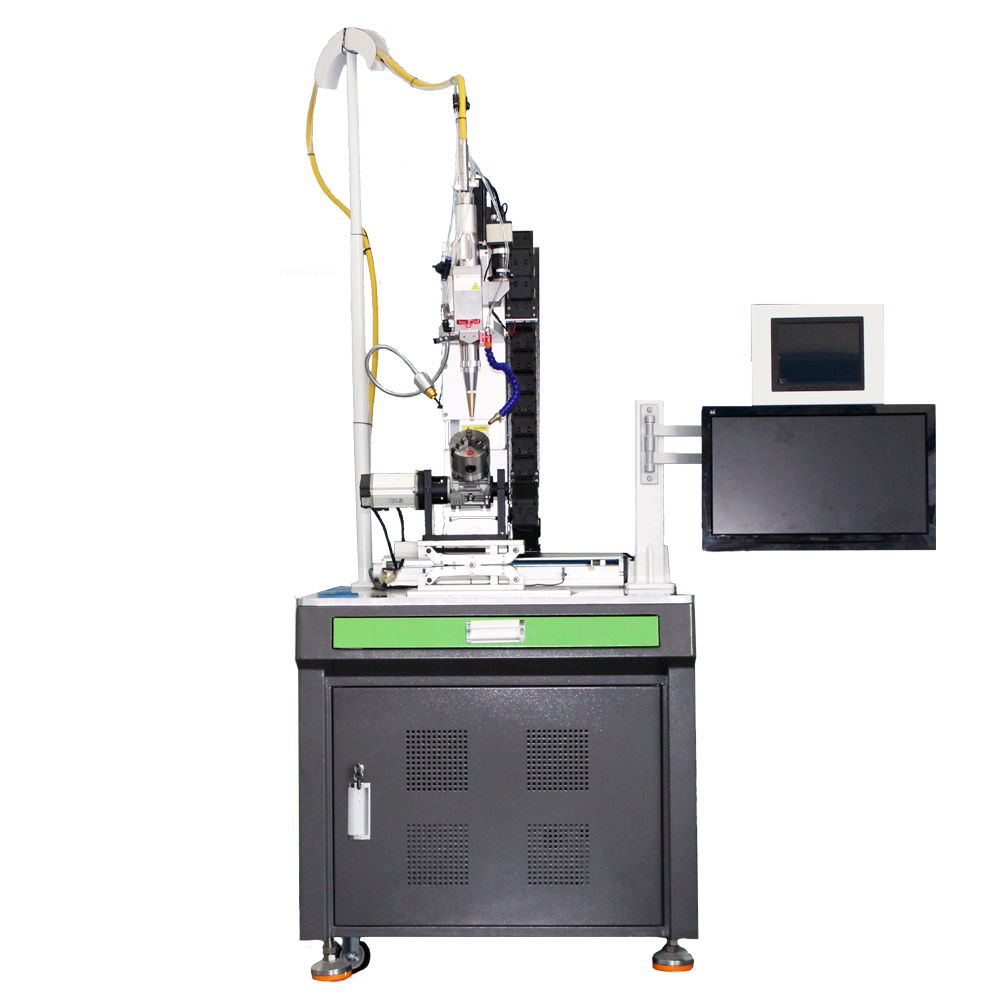

The chiller part of the laser marking machine is mainly composed of several major accessories such as important compressors for refrigeration, water pumps, fans (plus heat pipes, control systems, cold coal and its pipes). During work, pay attention to changing the water every month. Generally, high-quality pure water is used, and a filter needs to be configured on the waterway. Many buyers do not know the working principle of the cold water tank after choosing a laser device, and they do not know how to perform maintenance. Here are some introductions:

The working principle of the laser chiller is to inject a certain amount of water into the water tank inside the machine, cool the water through the chiller refrigeration system, and then send the low-temperature cooling water to the equipment to be cooled by the water pump. It rises and then returns to the water tank to achieve the cooling effect. The cooling water temperature can be automatically adjusted according to requirements, and long-term use can save water. Therefore, the laser chiller is a standard energy-saving device.

If the cooling effect of the cold water tank of the laser marking machine is poor, you can feed it back to the seller of the equipment to have it checked and repaired in time. You can also check whether the temperature of the chiller installation is too high, which causes poor heat dissipation or the condenser fin Whether the area is dirty or the filter is not cleaned.

When using a laser marking machine, we should pay attention to two points: one is to ensure that the water circulation is unblocked before the marking machine is turned on; the other is to keep the cooling water clean at all times. As long as this is done, the marking machine can keep working for a long time.