Which laser marking machine is suitable for marking wood?

Which laser marking machine is suitable for marking wood?

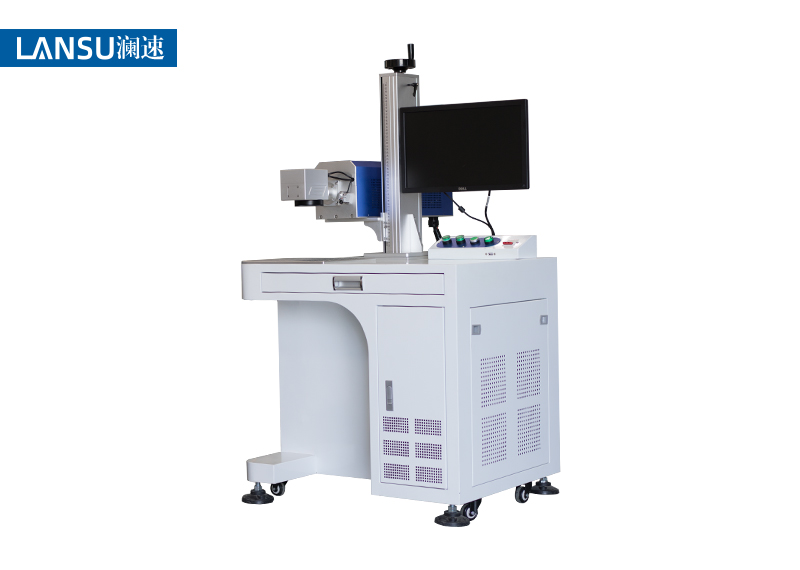

What to mark on wood? Which laser marking machine is suitable for marking on wood? To answer this question, Lansu Laser professional engineers can answer you, you can use carbon dioxide laser marking machine, fiber marking machine, UV marking machine! But not every machine can mark wood at will. Carbon dioxide marking machines are commonly used in the wood processing industry. This carbon dioxide laser marking machine is mainly for non-metallic materials, such as acrylic, leather, wood, plastic, ceramic products and so on.

Why can CO2 laser marking machine simply carve wood? This is because the CO2 laser is mainly different in wavelength from the YAG machine, so he is better at engraving and processing non-metal materials such as wood.

The CO2 marking machine can be used to engrav LOGO trademarks, text patterns, two-dimensional codes, codes, security codes, serial numbers, etc. on wooden products, bamboo products, leather products, and silicone products. Very good results, often used to mark wood products.

The fiber laser marking machine is suitable for marking painted wood. It cannot be marked without ink or paint. In addition, it can also mark all kinds of plastic transparent keys, IC chips, digital product parts, jewelry, sanitary ware, clocks and glasses, electrical appliances, electronic components, hardware accessories, hardware tools, auto and motorcycle accessories, and plastic products. , Medical equipment, building materials and pipes. It is a good hand for marking metal products. Of course, plastic marking is not a problem.

The UV laser marking machine is suitable for fine marking. Some wood products that require high accuracy and sharpness of the effect can be processed by the UV marking machine.

Laser marking machine has the advantages of clear, durable and beautiful marking. The engraved items have fine patterns, and the small line width can reach 0.04mm. The marking can be printed on any regular or irregular appearance, and the workpiece will not generate internal stress after marking, which guarantees the original accuracy of the workpiece. Does not corrode work surfaces and is free of wear, poison and pollution. High processing efficiency and fast marking speed.