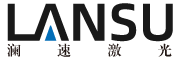

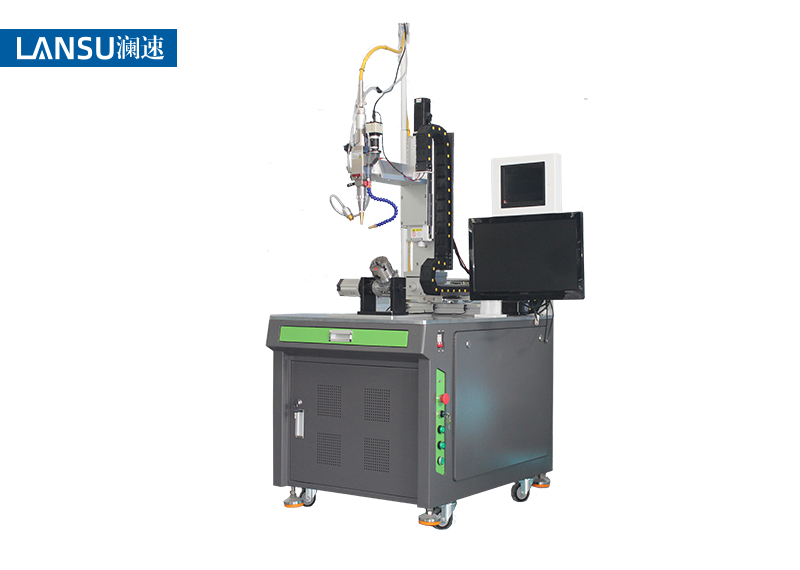

Operation steps of Lansu laser welding machine

Operation steps of Lansu laser welding machine

Laser welding is the use of high-energy laser pulses to locally heat the material in a small area. The energy of laser radiation is diffused into the material through thermal conduction, and the material is melted to form a specific molten pool. It is a new type of welding method, which has many applications in many industries. The following briefly introduces the operation steps and some precautions of laser welding machines:

Preparations before starting: check the power of the laser welding machine, whether the water cycle is normal; check whether the gas link of the equipment in the machine is normal; check that the surface of the machine is free of dust, spots, oil, etc.

First, start

1. Turn on the power and turn on the main power switch;

2. Turn on the water cooler and laser generator in order;

3. Open the argon valve to adjust the gas flow;

4.Enter the parameters of the job to be executed at that time

5. Perform welding operations;

Second, shutdown

1. Exit the program and close the laser generator

2. Close the dust collector, water cooler and other equipment in order;

3.Close the argon gas bottle valve

have to be aware of is:

1. During the operation of the laser welding machine, if you encounter an emergency (water leakage, abnormal laser sound, etc.), you need to press the emergency stop immediately and cut off the power quickly.

2.Be sure to turn on the external circulating water switch of the laser welding machine before operation.

3. Do not place flammable and explosive materials on the laser light path or where the laser beam can reach to avoid fire and explosion.

The above is a brief description of the operation steps of Lansu Laser Welding Machine. If you want to know more related information, welcome to enter Lansu Laser's official website for consultation.