Marking and cutting of laser marking machine on PCB

Marking and cutting of laser marking machine on PCB

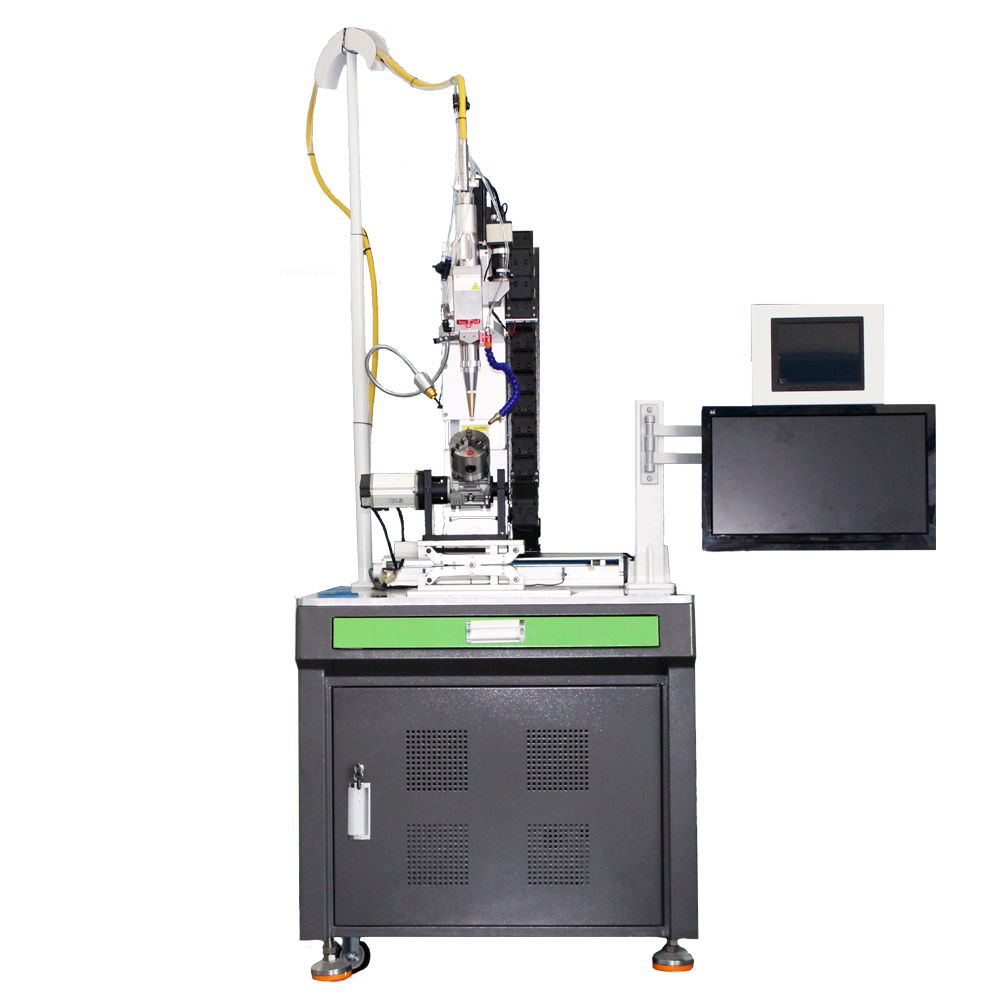

The PCB is an important electronic component, a support for electronic components, and a carrier for the electrical connection of electronic components. Almost every kind of electronic device, from electronic watches and chargers to computers and communication electronic devices, uses PCB boards. Laser marking machine has been applied in PCB board processing industry for a long time and has developed rapidly.

In order to better control product quality, it is necessary to record relevant production information to facilitate the full traceability and quality control of electronic products. The internal structure of the product-PCB marking information must be clear, and the productivity of laser marking machines must be improved at the same time. , Reduce costs, reduce pollution, and adapt to the development of multi-variety, small-batch production.

The laser marking machine identifies the character string, one-dimensional code, two-dimensional code and other information on the PCB board, uploads it to the database through camera identification, automatically removes substandard products, and realizes product quality traceability throughout the entire internal process, from source supplier information to Product outbound data tracking, full-process tracking, improve product quality, and effectively implement product management and control.

Laser marking machine high performance laser, good marking quality, high precision CCD can be connected to customer MES system data information. It can realize automatic positioning, code reading and rating, and can be seamlessly connected with mature SMT pipelines. It only needs to be controlled by computer, simple operation, environmental protection and energy saving, and fully meet the existing high quality marking requirements of the PCB industry.

At present, laser marking machines are mainly used in some applications that require finer and higher precision. Laser marking machine can be applied to electronic components, integrated circuits (ICs), electrical appliances, mobile phone communications, hardware products, tool accessories, clocks and watches, jewelry, auto parts, plastic buttons, building materials, PVC pipes and so on.