Development of laser marking machine in the field of chip processing

Development of laser marking machine in the field of chip processing

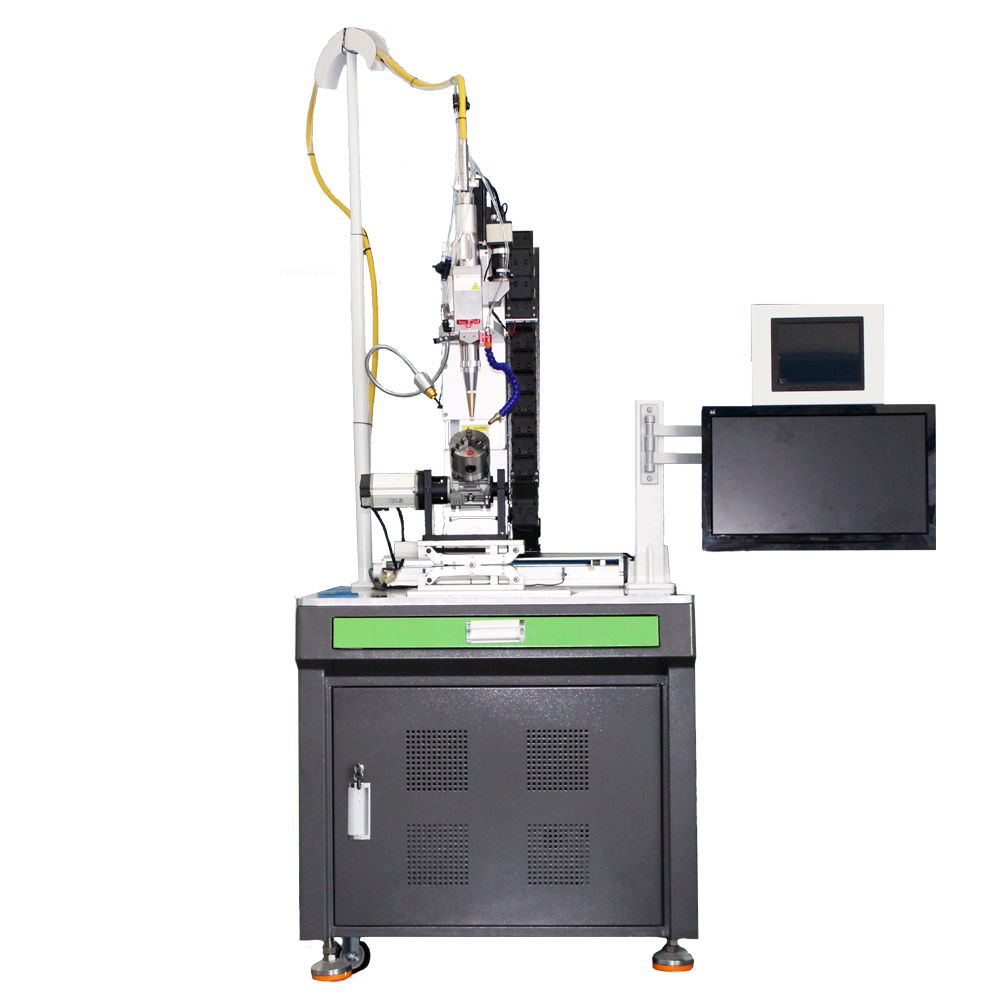

Today, more and more IC chip manufacturers choose to use laser marking machines for identification. IC chips can integrate a variety of electronic components on the silicone board to form circuits to achieve certain specific functions. In order to distinguish the chips and facilitate traceability And anti-counterfeiting, you need to make some marks, such as numbers, letters, compliance, etc., and the area of the chip is small, the marking requirements are high, then only the laser marking machine can meet this requirement on the market.

The material used for the integrated electronic chip is very special. In our long-term application or printing, it is easy to cause chip defects. There are many defective products, making the identification difficult to identify, but using a fiber laser marking machine on the IC chip When marking, these problems can be completely ignored. Because the fiber laser marking machine is used to mark on the chip, it is mainly engraved in a non-contact form, so that not only will the chip surface not have any scratches, the surface will also be very smooth.

Laser marking machine has the advantages of no pollution, high speed, high quality, great flexibility, and no contact with the workpiece. The automatic laser marking system is a comprehensive application of modern laser, computer, electrical control, mechanical design and other opto-electromechanical subjects. The laser marking machine has good marking effect, fast marking speed, durable and wear-resistant logo, and high degree of automation. With these advantages in the chip processing field, it has become more prominent and has become more and more widely used and developed faster and faster.