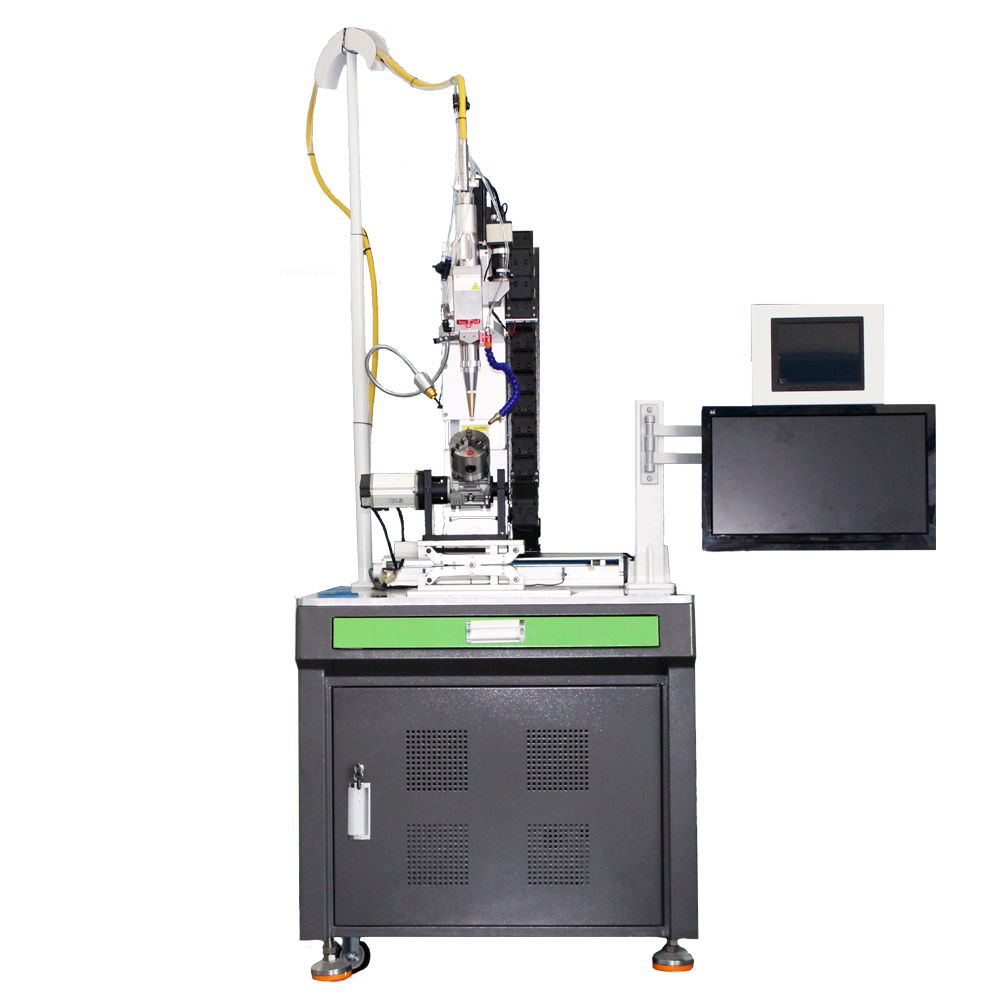

Laser marking machine for marking on glass

Laser marking machine for marking on glass

Everyone knows that glass is an amorphous body. The molten glass is rapidly cooled (undercooled), and each molecule forms glass because there is not enough time to form crystals. It is fragile, but it is also a very common material in mass industrial production. What kind of application does laser marking machine have on glass?

Laser marking machine can engraving exquisite patterns and patterns on glass, as well as logo parameters, with fine marking lines, which is very suitable for marking patterns or text information on the surface of glass materials. There are several ways to use laser to mark on glass.

1.Multiple laser irradiation method

The laser marking machine uses a single laser radiation to generate a marked contour mark on the glass surface. After a few days, the laser extends to the area near the original mark to form fragments, and then uses multiple radiations to heat the area adjacent to the marked area through heat conduction. The formation of stress gradients in these areas reduces the possibility of secondary cracking. This method is very effective for marking on soda lime glass and borosilicate glass. Small glass bottles filled with liquid medicaments and glasses in daily life can be marked using this method.

2.Creating a crack-like surface crack method

The laser marking machine adopts the process of heating and cooling to change the affected glass surface. This method is not immediately visible. It starts to generate a cabinet-shaped crack along the laser marking area after a slight pressure. This method can print clear marks on high-quality automotive glass, which requires purity to the surface.

3. Discrete point formation ring crack method

Laser marking machines use a series of annular cracks to form text, bar codes, square or rectangular codes, and other shape code patterns. There are many CO2 laser marking machines that use this method. CO2 laser marking machines set a parameter for marking and marking on glass, which results in less cracks. Discrete points appear to form annular cracks. Glass produces low-density annular cracks through heating and cooling cycles. When the glass is heated, it expands and squeezes the surrounding materials. When the temperature rises to the softening point of the glass, the glass rapidly expands to form a low-density material protruding from the glass surface.