Characteristics and development of flying laser marking machine

Characteristics and development of flying laser marking machine

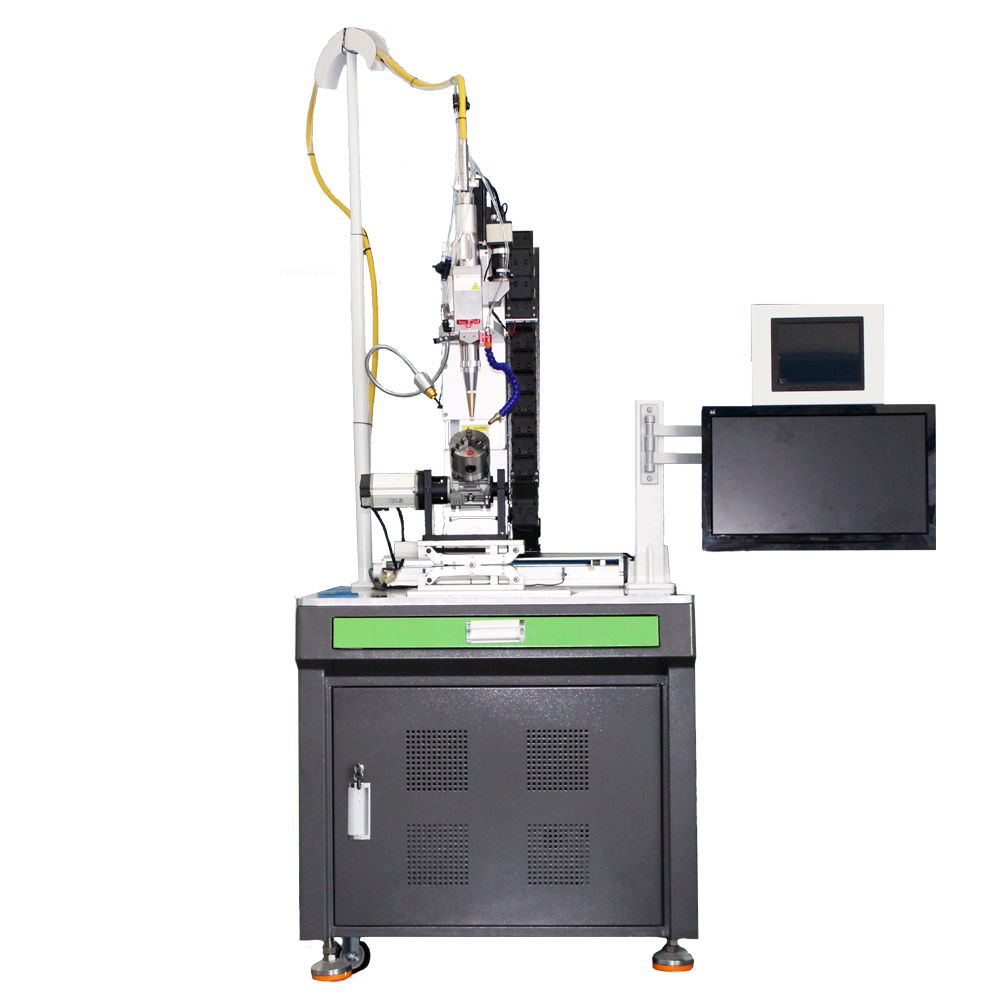

With the diversified needs of marking, automatic production, assembly line production, and the requirements of unconventional interface materials, common static laser marking machines have been unable to meet the diverse work needs. Online flight marking has emerged as the times require, and it has become A standard device for marking on all types of cables, packaging, pipes, beverages and other materials.

The flying laser marking machine uses the principle of movement and uses vector marking to move the cursor in the direction of the unidirectional axis to mark the moving object. The device has strong text layout and graphic processing functions, and can automatically generate batch and serial numbers, so it can achieve 24-hour discontinuous work. The plugged intelligent control interface can be flexibly connected with various automation equipment and sensors. According to specific conditions, the software functions can be flexibly modified.

To put it simply, flying laser marking machine means to follow the assembly line and cooperate with industrial automation. Where the workpiece is marked in a certain period of time is a reflection of automation. The static laser marking is a semi-automatic marking mode. Manual loading and unloading, placing the workpiece on the work platform, and manual cutting after finishing the marking.

The operation of the current flying laser marking machine not only brings considerable prospects to the industrial efficiency, but also has a functional nature of saving people flow, time and energy. Therefore, the process of coding and marking is performed, and the products in the industry flow on the production line in an assembly line, and then the efficiency in industrial production is effectively improved, and the operating efficiency of production is also effectively increased.