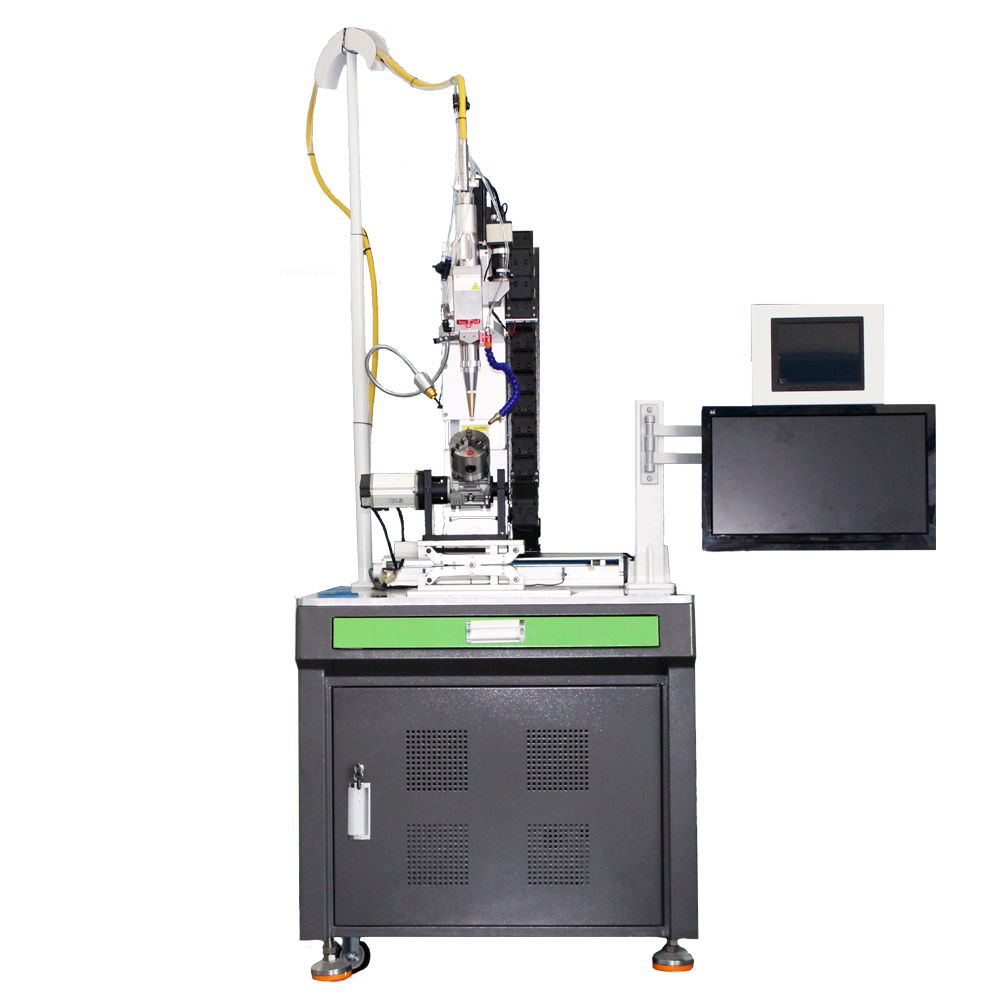

Laser marking machine marking custom metal plate

Laser marking machine marking custom metal plate

The nameplate is also called the nameplate. The materials used to make the nameplate are zinc alloy, copper, iron, aluminum, stainless steel, etc. However, aluminum is mainly used for production, because the processed nameplate is relatively high-grade, durable and does not rust. Each manufacturer has a unique information symbol on the nameplate identification, such as model, specifications, production batch, production date and other information. Today, laser marking has become a common technology for product identification, and its application range is becoming more and more widespread.

Laser marking machine quickly becomes a better choice for marking and coding due to its unique advantages such as fast marking speed, fine effect, strong adaptability and maintenance-free. Full air cooling, no consumables, no maintenance, low use cost, low power consumption, flexible optical fiber output, more convenient use, power saving In addition, the laser marking machine has an integrated modular design, which is convenient for maintenance, small in size, and the marked marks have good wear resistance, are not easy to erase, and have strong anti-counterfeiting functions.

In the process of making nameplates by screen printing, some organic solvents and heavy metal elements and other chemical raw materials may have a certain impact on the processing staff and waste disposal, and the ink also volatilizes, which is harmful to individuals and the environment. May be a hidden danger. Laser marking is dust-free and smoke-free, which is a more environmentally friendly processing method.

In addition to laser marking machines often used in the metal nameplate industry, they can also be applied to the surfaces of metals and some non-metallic materials such as bearings, meters, plastics, valves, electronic components, communication equipment, hardware, mobile phone accessories, jewelry, and auto parts. Print the engraving code.