Laser marking machine marks logo on vacuum cup

Laser marking machine marks logo on vacuum cup

The weather is gradually entering the severe winter. Everyone is usually shivering in the cold weather, and the ice cream is temporarily put on hold. It is replaced by the boiling water in the insulation cups. Various types of insulation cups have become popular in the market. As a heartwarming winter gift, sending friends to colleagues, the purchase volume is rising rapidly, which undoubtedly increases the use of laser marking machines.

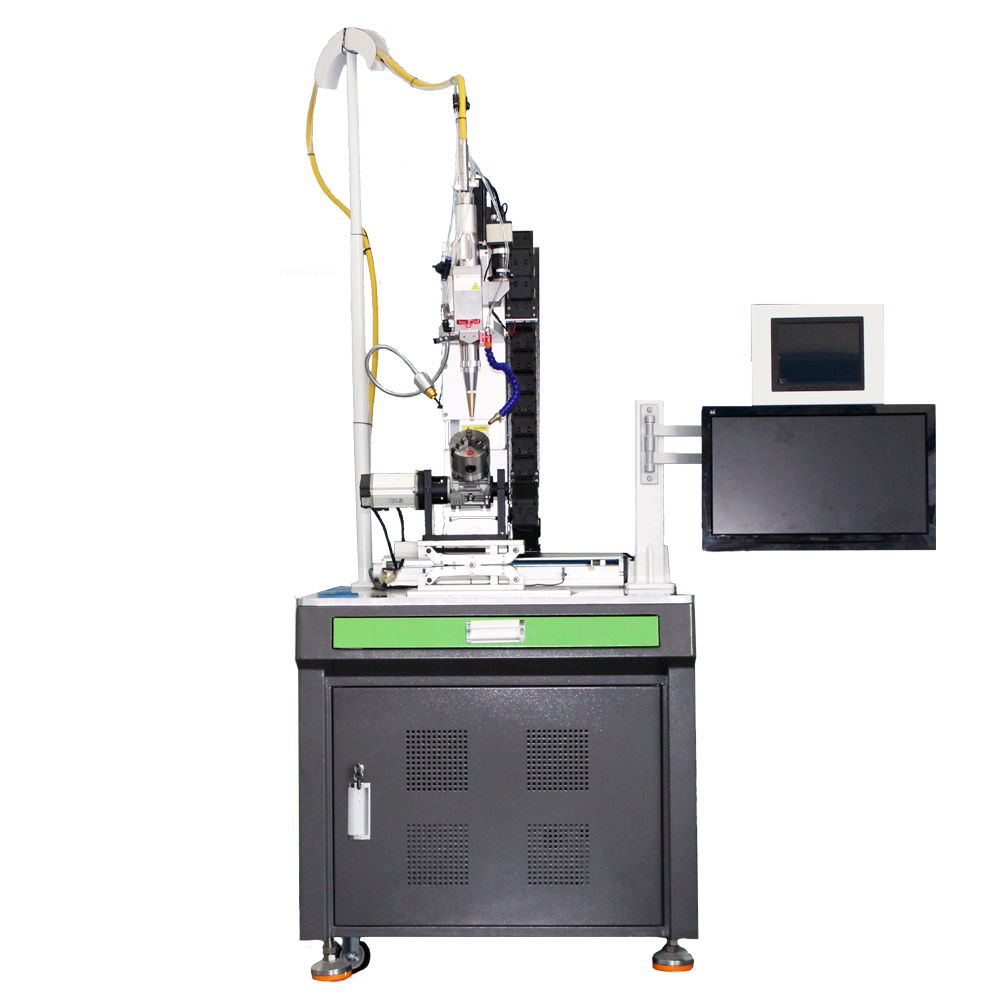

The thermos cup shell is generally two types: metal stainless steel or plastic. It needs to be marked with the brand logo, simple parameters, or retrospective two-dimensional code. Selecting a fiber laser marking machine is sufficient. It can be used for multiple purposes. Marking metal materials, and marking on plastic materials, strong adaptability, and flexible marking, 360-degree rotation processing in the cylindrical insulation cup body, clear and beautiful logo, flat and delicate tentacles, no burrs, durable It is stronger than ordinary labeling or ink coding, and will not easily fade and blur.

The more popular the insulation cup is, the higher the processing speed requirements are. The laser marking machine can ensure the marking quality and the marking speed can keep up with the rhythm of the production line. It can complete the marking of a product in a few seconds. , High-quality lasers and high-speed scanning galvanometers make the machine performance more stable, environmental protection, energy saving, and low failure rate. Creating high-quality insulation cups improves competitiveness and promotion efforts, and also allows manufacturers to save a lot of labor costs and consumables costs, and move towards the direction of automation development. .