Which laser marking machine is more suitable for marking glass?

Which laser marking machine is more suitable for marking glass?

Green laser marking machine and ultraviolet laser marking machine are both a type of laser marking machine, which are divided into green light and purple light according to the different lasers. One of our customers raised a question when marking glass cups: Is it better to use purple light or green light for marking glass products?

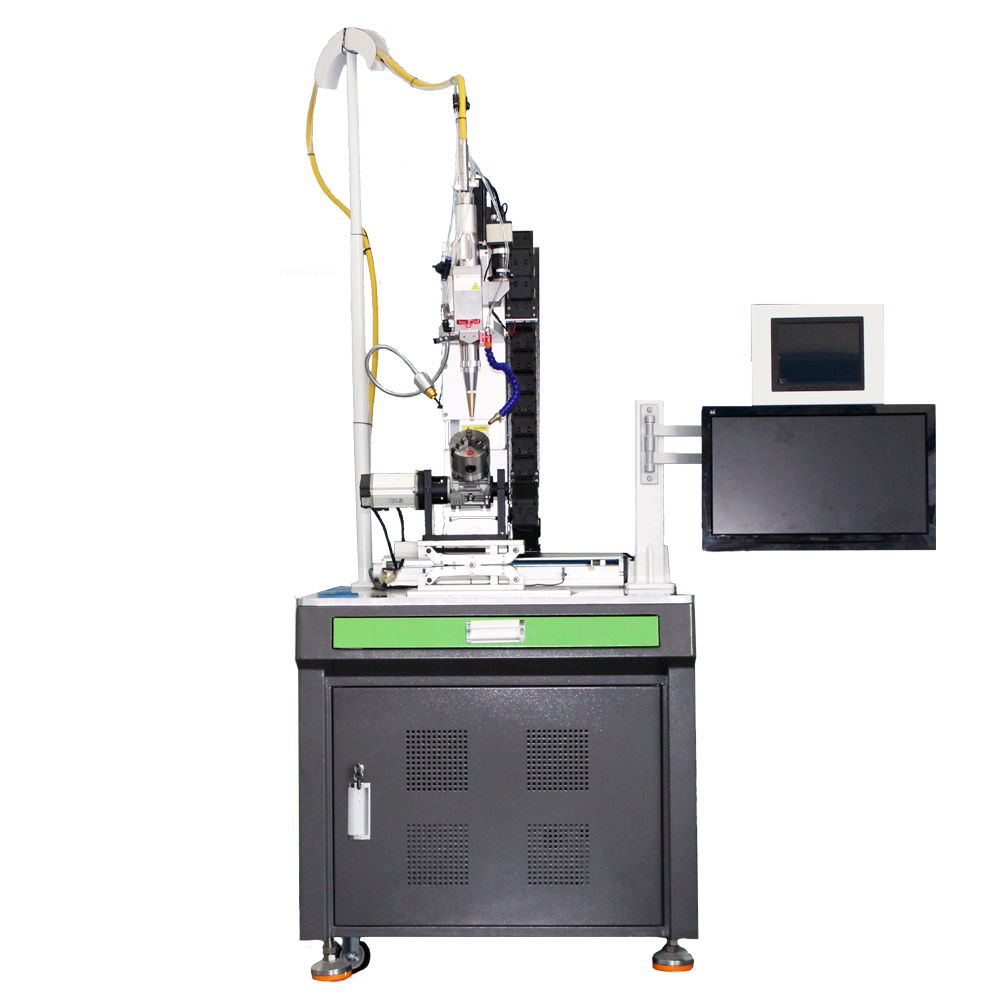

After understanding the customer's product materials and requirements for effects, our salesman gave an accurate and reasonable marking solution-this type of product is more suitable for using UV laser marking machine. But for many lay customers, how to distinguish the two devices? Let's start with their respective characteristics and applicable materials:

UV laser marking machine: High-resolution marking of plastics and corrosion-resistant materials

The output wavelength of the UV laser marking machine is 355nm, which can provide unique marking characteristics. It is a device suitable for fine marking. Customers who have high requirements for the clarity and effect of marking will generally choose purple light marking. The 355nm wavelength further increases the range of plastic materials that can be marked. In addition, it belongs to cold light processing and can be used to control the heat input to the material. The power is much smaller than other marking machines, and marking on glass has advantages.

Green laser marking machine: suitable for certain plastics, silicon and reflective metals

The green light output by the laser is at a wavelength of 532nm, which can achieve a good contrast mark, can achieve soft marking of silicon materials for plastic materials, and can also achieve high-quality gold and silver reflective marking materials. The more typical application is carving and engraving on the surface of crystal. The effect of marking on glass which is a fragile material may not be as good as that of UV laser marking machine.