Laser marking machine marking radiator

Laser marking machine marking radiator

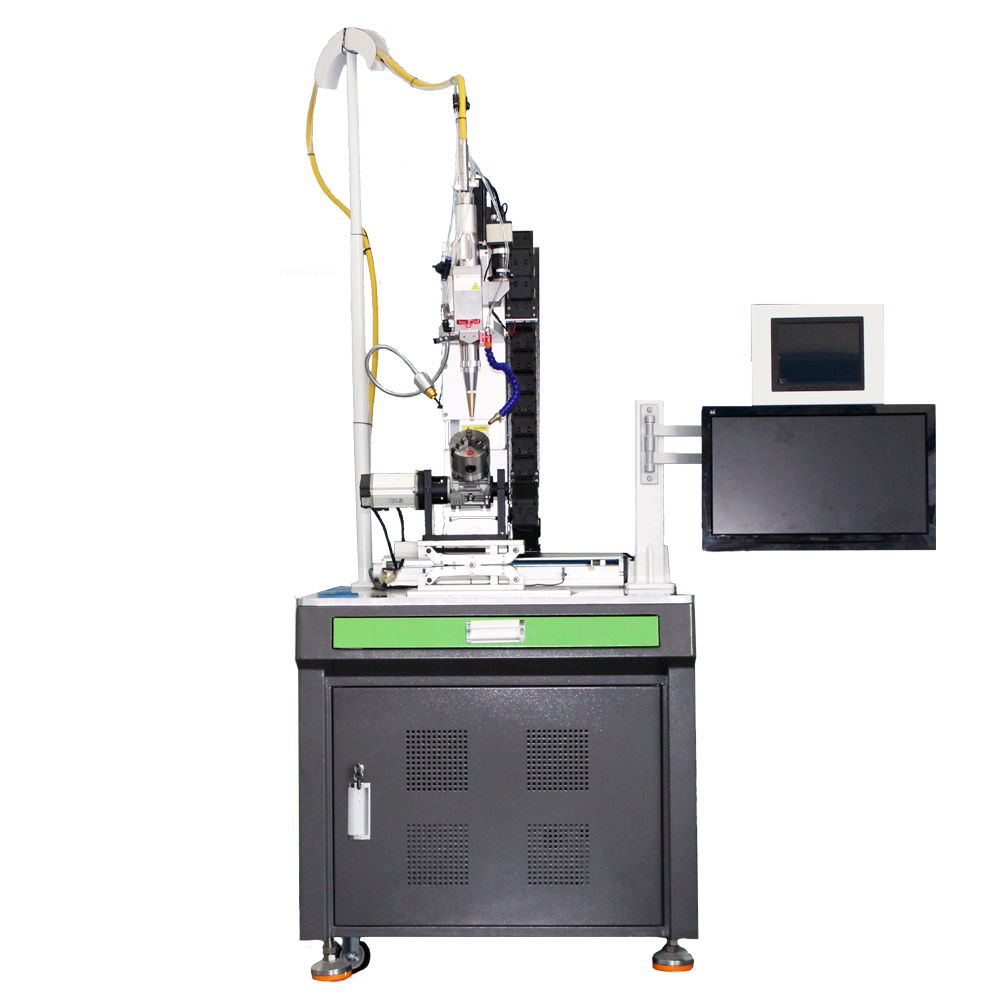

We often find that almost all products will be marked with the production date, logo, parameters and other information. These marks cannot be erased, are durable, and will not fade. This is the laser marking machine marking technology. This machine can mark metal and most non-metallic materials. In addition to our commonly used mobile phones, led lights, chargers, etc., radiators are now processed with laser marking machines to enhance the brand recognition of products. Product anti-counterfeiting also has extraordinary significance.

The laser marking machine has very low operating costs, requires no maintenance, and has a long warranty. In addition, the power consumption is not very large. Compared with the traditional processing equipment, the initial investment is slightly more expensive, but in the long run. It is still very valuable in the later period. The laser marking machine consumes low energy and requires no consumables. Easy processing.

The laser marking machine is processed by a non-mechanical "light knife". It can print marks on any regular or irregular surface, and the workpiece will not generate internal stress after marking, ensuring the original accuracy of the workpiece. No corrosion to the work surface, no wear, no poison, environmental protection and energy saving, no pollution.

More common is the laser marking machine on stainless steel, carbon steel, copper, aluminum, alloy and other metal materials for marking processing. In the sheet metal industry, hardware industry, spare parts industry and other fields, all kinds of metal materials need to be accurately and accurately marked. Compared with traditional processing methods, laser marking machines are particularly suitable for marking complex graphics due to their high precision characteristics. The fast marking speed and the one-shot marking greatly expand their application range.