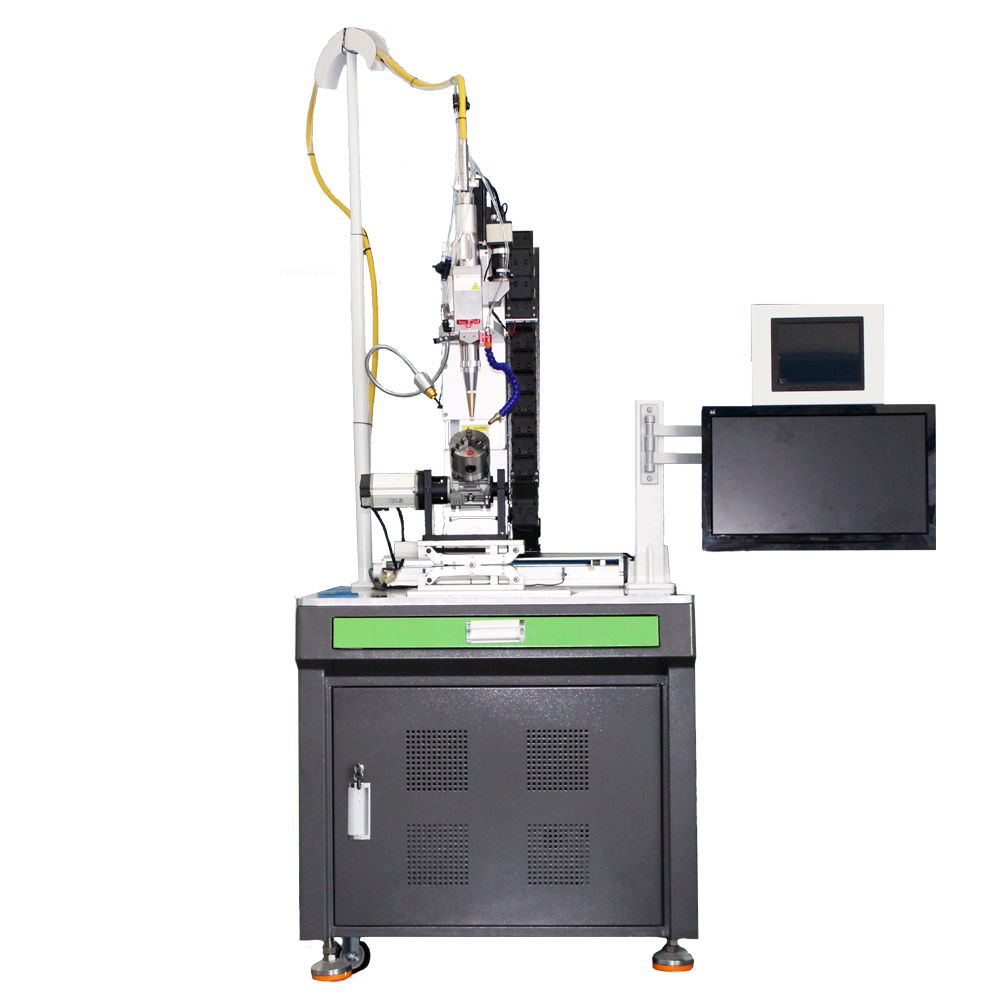

Application of Lansu Laser Marking Machine in Plastic Industry

Application of Lansu Laser Marking Machine in Plastic Industry

Plastic products have an irreplaceable role in our lives, have a profound impact on our daily lives, and occupy a huge market share, such as household goods, faucets, mobile phone cases, lamps and other industries we can see Plastic shadow.

The laser marking machine is characterized by non-contact processing, no pollution, high operation accuracy, fast marking speed, easy operation and durable marking effect. Not only does it give smooth and textured marking information to plastic products, but it also does not require expensive preliminary work and subsequent trimming work. In addition, it can also be equipped with related automation related facilities according to actual processing needs to achieve large-scale production needs. . Compared with the cost of consumables of traditional marking systems, it can be said that it has saved a lot of money for enterprises. The laser of the laser marking machine is a consumable-free laser with a life of up to 100,000 hours. Only 0.5 degrees / hour.

The ink used in the ink pad printing method is not completely non-toxic and harmless to the human body. Inks and solvents are highly volatile substances, which will produce more chemically toxic residues, which not only pollute the environment but also harm the health of workers. It is difficult to pass the increasingly stringent environmental protection testing, and it is gradually being phased out internationally. The product. In the United States, the use of inkjet machines to mark the inner packaging of pharmaceutical products has been banned, and all laser marking machines have been used.

Although the current price of laser marking machines is not as cheap as traditional equipment, the durable, high-definition, high-quality, wide application, and long-lasting characteristics of laser equipment have allowed manufacturers to invest a lot in return for laser equipment. It is gradually pushing the current processing of plastic products to a new level, providing a new direction for the current marking processing of plastic products.