What precautions should be taken when operating the Lansu laser marking machine?

What precautions should be taken when operating the Lansu laser marking machine?

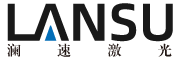

Laser marking machine is a kind of mechanical equipment and has many applications in many industries. Even if the performance is stable and it is not prone to failure, it needs regular maintenance during use. The following are some precautions when operating Lanspeed laser marking machine:

1. Within one meter of all exhaust holes of the laser machine, no objects should be stacked. Otherwise it will affect the heat dissipation effect and shorten the life of the device.

2. Keep the fire extinguisher within easy reach; turn off the laser or shutter when not processing; do not place paper, cloth or other flammable materials around the unprotected laser beam.

3. Before using the laser marking machine, the power outlet must be grounded.

4. The laser machine is an electrical industrial product. Pay attention to moisture and shock resistance during use.

5. If there is any abnormal situation, please contact the company's after-sales personnel at any time. Do not disassemble equipment parts without permission.

6. Don't process a material without knowing whether it can be irradiated or heated with a laser to avoid the potential danger of smoke and vapor.

7. During the laser marking process, do not touch the beam with anything, especially parts of the human body.

Laser marking machine is a semi-automatic marking processing equipment in the processing industry. It needs regular maintenance during use. Pay attention to the above points to ensure the stability of production and processing, and also make the life of the laser marking machine. Longer.