- Fiber laser marking >

- 20W fiber laser marking machine

- 30W Fiber Laser marking machine

- 50W Fiber Laser marking machine

- Ultraviolet laser marking >

- 3W UV Laser Marking machine

- 5W UV Laser Marking machine

- 10W UV Laser Marking machine

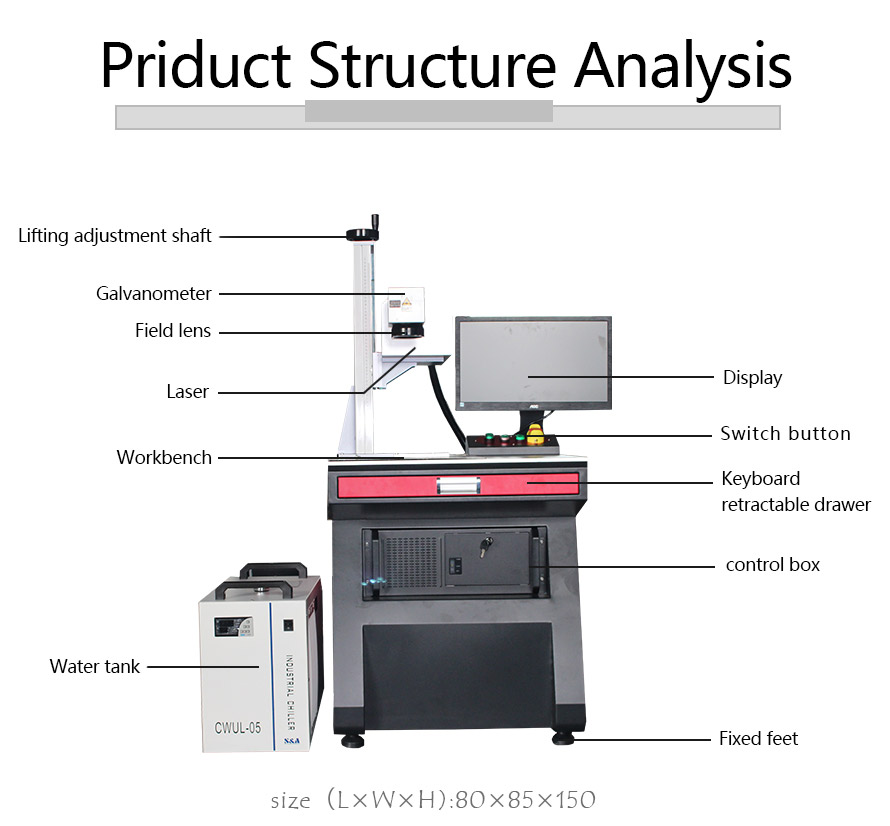

The Structural Characteristics of 10W UV Laser Marking machine

10W UV laser marking machine belongs to the series of laser marking machines, but it is developed by using 355nm UV laser. This machine uses third-order intra-cavity frequency doubling technology. Compared with infrared laser, 355 UV light focusing spot is very small. To a large extent reduce the mechanical deformation of the material and the small thermal impact of processing, because it is mainly used for ultra-fine marking and engraving, especially suitable for food, pharmaceutical packaging material marking, micro-holes, high-speed division of glass materials and Silicon wafers perform complex pattern cutting applications.

Application industry of 10W UV Laser Marking machine

The UV laser marking machine is mainly based on its low-power laser beam, which is especially suitable for ultra-fine processing in the high-end market. Cosmetics, pharmaceuticals, video and other polymer materials are marked on the surface of packaging bottles. Better than ink coding and no pollution; marking and dicing of flexible pcb boards; micro-hole and blind hole processing of silicon wafers; two-dimensional code marking of LCD liquid crystal glass, hole punching on glass appliances, metal surface plating marking Plastic buttons, electronic components, gifts, communication equipment, construction materials, etc.